"Racescort666" (Racescort666)

"Racescort666" (Racescort666)

02/03/2014 at 21:57 • Filed to: Truck Yeah, semi trucks, info

10

10

98

98

"Racescort666" (Racescort666)

"Racescort666" (Racescort666)

02/03/2014 at 21:57 • Filed to: Truck Yeah, semi trucks, info |  10 10

|  98 98 |

So in light of recent !!!error: Indecipherable SUB-paragraph formatting!!! and !!!error: Indecipherable SUB-paragraph formatting!!! , I decided that it might be a good idea to throw some words together on what I know about semi truck safety systems. I don't work for Bendix or anything, their promotional stuff and information is just the easiest to find. The primary goal of this blurb is to talk about what systems are out there and how they operate.

!!! UNKNOWN CONTENT TYPE !!!

The TL;DR version is watch this video of trucks driving on snow and stuff:

Air Brake System Overview

I thought I'd throw together an overview how air brakes work so that everyone is on the same page. An air brake system on a semi truck operates differently than the hydraulic brake in your car. In your car, you apply force to the pedal which is multiplied by the mechanical advantage of the hydraulic system:

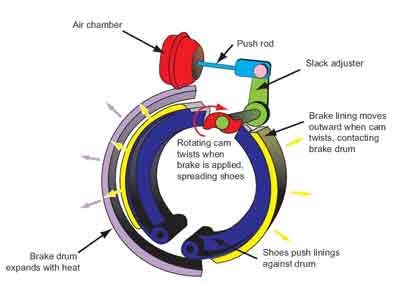

Air brakes don't work by multiplying the input force from the pedal so lets start with the air brake chamber.

The air brake chamber actuates the push rod that operates the brake linkages.

There are air disc brakes along with drum brakes but drums are most common and the chamber operation is the same.

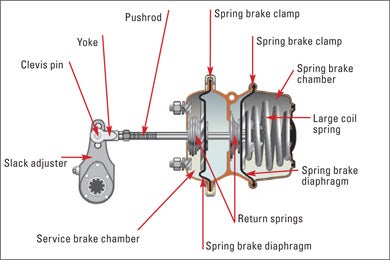

Service brakes are all pressure to apply while park/emergency brakes are pressure to release. This is accomplished by having a dual chamber on the rear tractor axles as well as the trailer axles. In the diagram below the large coil spring is for the park brake spring (spring brake). When the park brake circuit is unpressurized, the coil spring actuates the push rod engaging the brakes. When the park brake circuit is pressurized, it releases the spring brake. The service brakes are applied when the adjacent chamber is pressurized operating the same pushrod.

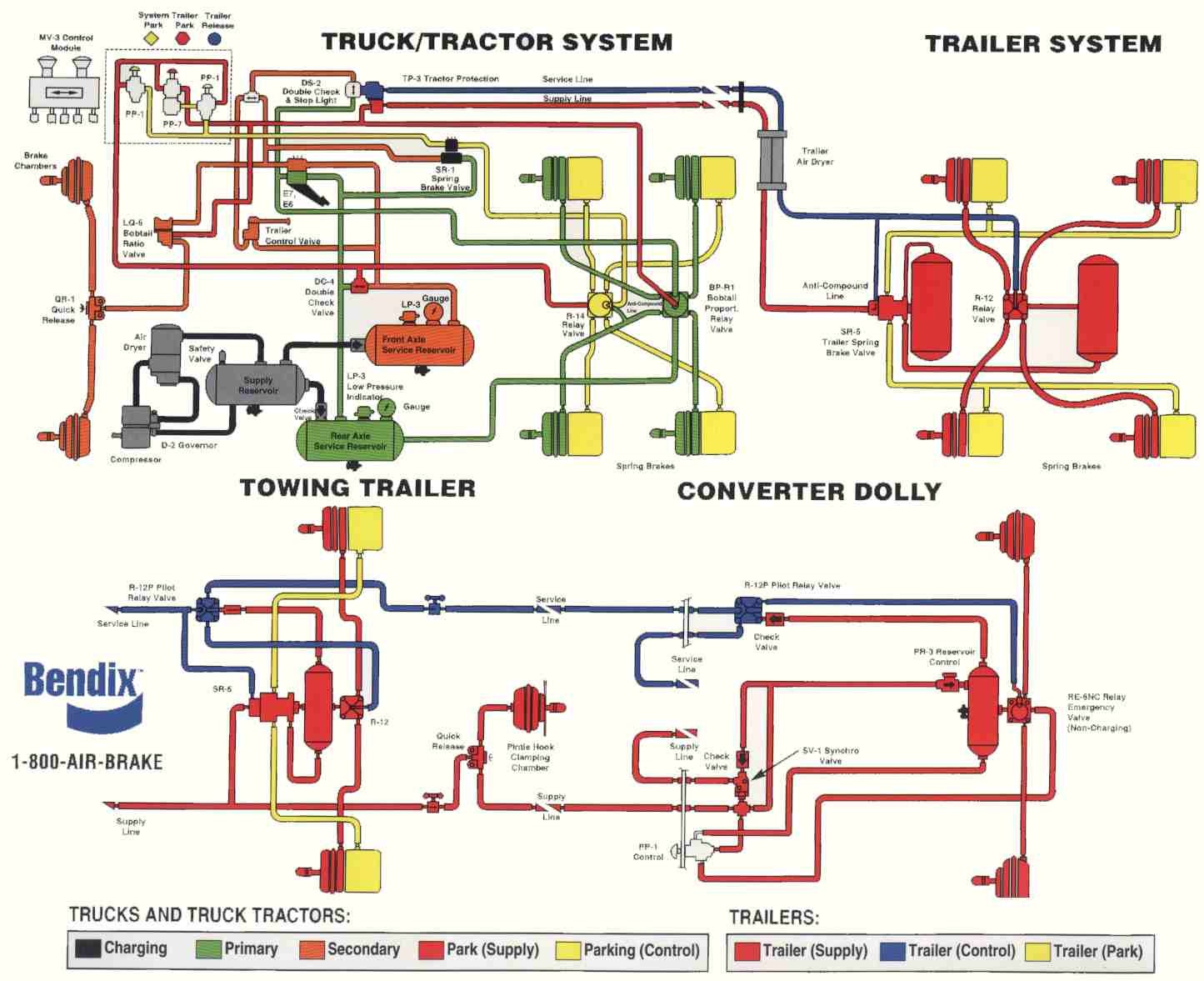

Below is a typical tractor/trailer plumbing diagram. Air pressure for the system is generated by the truck's on board, engine driven air compressor. The park brake circuit in yellow, the service brakes are the green (primary), orange (secondary), and red (trailer) lines.

More info on the charging system in this video:

So now that we have a handle on how the chambers work and the air system, a quick word on the treadle valve. The treadle valve is the foot actuated valve that releases air from the air tanks either directly to the chambers or to a relay valve. The relay valves operate the same way as the treadle valve except that instead of your foot regulating the air, it's air pressure, kind of like a transistor. There is usually 1 at the rear axles and 1 in the trailer.

Safety Systems

ABS

ABS is the first safety system to be implemented and is also required for on highway air brake equipped vehicles. The general way that they operate, is by having an electronically controlled modulator bleed air pressure from the brake chamber at specific wheels when the system senses wheel slip to modulate brake torque. Other than this, the ABS system on an air brake truck operates very similarly to the ABS on your car, with the wheel speed sensors sending speed data to the ABS computer.

Stability Control

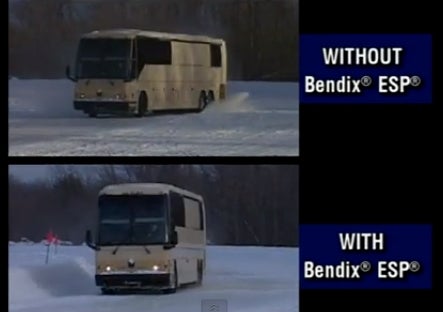

Stability control builds on the ABS system with the addition of several sensors (steering angle sensor, yaw sensor, in addition to wheel speed sensors) and several electronically controlled valves. Again, this is similar to stability control systems in cars in detecting the intent of the driver and the behavior of the vehicle. The difference is the addition of electronically controlled valves to apply air to the chambers and the modulators bleed air from the individual chambers to control the orientation of the vehicle. Skip ahead to 2:25 if the embedding didn't work although the entire video is pretty informative.

The stability control system will work with both the tractor and trailer brakes to help prevent a rollover and jackknifing. It will automatically brake the trailer and the appropriate tractor wheels to keep the tractor under control. It will control both understeer and oversteer.

I know we all complain about electronic nannies on our cars, I certainly do, but it's hard to deny that modern stability control systems on trucks are a huge improvement on safety.

desertdog5051

> Racescort666

desertdog5051

> Racescort666

02/03/2014 at 22:34 |

|

Great post. I drove a truck a long time back. We had none of these devices. But, the roads had so many fewer morons on them, too. It is impressive how these things have improved control so much. We ran midwest to west coast without Jake brakes. My boss thought they were too hard on the engine. Almost every trip I would have to get a wheel seal replaced because of excess brake heat.

Rock Bottom

> desertdog5051

Rock Bottom

> desertdog5051

02/03/2014 at 22:41 |

|

Crossing the Rockies without a Jake Brake must have taken some huge... nerves! I spent time behind the wheel of a truck in nice, flat Michigan years ago and often wished I had one. The big hills along the Continental Divide must have been hard on the old sphincter!

desertdog5051

> Rock Bottom

desertdog5051

> Rock Bottom

02/03/2014 at 23:00 |

|

The worst was the downhill after crossing the Sierra Nevada Mountains heading toward Sacramento, CA on I-80. Miles and miles of nothing but downhill. That was where I usually overheated the brakes the worst. Most trips I had to hit an exit ramp to let the brakes cool. The second worst was I-70 east heading toward Denver.

M54B30

> Racescort666

M54B30

> Racescort666

02/04/2014 at 00:29 |

|

I have a CDL and the air brake test is arguably the hardest. So many numbers to memorize - max pressures, minimum pressures, pressure build rate, pressure bleed rate, etc etc on top of what seems like 450 system components to memorize. My tester also made us troubleshoot hypothetical brake problems during our test which was not easy.

Racescort666

> desertdog5051

Racescort666

> desertdog5051

02/04/2014 at 10:08 |

|

Thanks for the feedback. According to Bendix, the stability control system integrates with engine brakes and transmission retarders. Part of the integration is reducing engine power in the event of a system activation. It's kind of hard to tell in the videos but almost every truck tested has significantly reduced speed through the corners.

Boss2452stolemylunchmoney

> Racescort666

Boss2452stolemylunchmoney

> Racescort666

02/04/2014 at 10:13 |

|

I do not understand why they don't use hydraulic brakes. It's not like it's impossible... Caterpillar uses hydraulic brakes on their large off highway trucks.

Racescort666

> M54B30

Racescort666

> M54B30

02/04/2014 at 10:15 |

|

There are considerably more parts with the stability control. When you key on, the ABS system cycles all of the valves but we were having problems with one of the trucks bleeding a ton of air during this key on cycle. It turns out that one of the valves was plumbed backward. That was frustrating.

Ralstig

> Boss2452stolemylunchmoney

Ralstig

> Boss2452stolemylunchmoney

02/04/2014 at 10:19 |

|

Hydraulic brakes stop working if they leak. Air brakes will still function with a leak.

Racescort666

> Boss2452stolemylunchmoney

Racescort666

> Boss2452stolemylunchmoney

02/04/2014 at 10:21 |

|

Aircraft also use hydraulic brakes but they still don't operate the same way as the ones in your car. i.e. mechanical force multiplication. Larger vehicles require so much braking force that this method of braking is impractical. They would still use an engine driven pump to generate pressure for a working fluid (hydraulic fluid or air, it doesn't matter) and the brake pedal would still operate a treadle valve to modulate brake pressure at the wheel ends.

While there are advantages to a hydraulic system, air is the industry standard and it would require a major overhaul of the entire truck industry to implement. All that, and the system still operates the same way.

ChuckFickens

> Boss2452stolemylunchmoney

ChuckFickens

> Boss2452stolemylunchmoney

02/04/2014 at 10:24 |

|

Also, it's a lot easier to connect a trailer's brakes to the tractor using air lines, using hydraulic lines would mean the system would need bleeding every time you hooked up a trailer.

BigHarv

> Boss2452stolemylunchmoney

BigHarv

> Boss2452stolemylunchmoney

02/04/2014 at 10:26 |

|

Wouldn't you have to bleed the system every time you hooked up to a new trailer?

thisisamazonman

> Racescort666

thisisamazonman

> Racescort666

02/04/2014 at 10:28 |

|

But you said that hydraulic brakes multiply the force of you braking, air brakes don't right? So won't the brakes be a lot more effective if they are hydraulic? Couldn't you just use air-brakes in the trailers (so that you don't have to bleed the system every time) and hydraulic brakes in the power unit?

satalac

> ChuckFickens

satalac

> ChuckFickens

02/04/2014 at 10:28 |

|

This is one of the big issues. That or they'd have to have a pump located on the trailer itself.

bobrayner

> Racescort666

bobrayner

> Racescort666

02/04/2014 at 10:28 |

|

Informative. Thanks!

Sky Blue

> Racescort666

Sky Blue

> Racescort666

02/04/2014 at 10:28 |

|

If I was drifting a bus...I don't care what anyone says...that'd be fun!!

Old-Busted-Hotness

> Boss2452stolemylunchmoney

Old-Busted-Hotness

> Boss2452stolemylunchmoney

02/04/2014 at 10:30 |

|

Brake fluid boils when it's overheated, and air doesn't. Stopping 80,000 pounds generates a lot of heat.

afrojim

> Boss2452stolemylunchmoney

afrojim

> Boss2452stolemylunchmoney

02/04/2014 at 10:30 |

|

If a leak is developed in hydraulic brakes you lose all braking ability. With air brakes, if a leak is developed the compressor can compensate for that until it can be fixed. A 2 ton car without brakes is a lot different from a 50 ton truck and trailer.

satalac

> M54B30

satalac

> M54B30

02/04/2014 at 10:31 |

|

Yeah, I've been trying to go over it with some employees at work that are trying to get their Class Bs. It is a lot of info to go over.

satalac

> Racescort666

satalac

> Racescort666

02/04/2014 at 10:33 |

|

The trucking company I used to work for was talking about getting the Bendix systems on their trucks before I left. Watched their videos on it and was impressed with it. If that particular job hadn't have been so horrible, I would have liked to have tried the system out. On a closed course of course.

Racescort666

> thisisamazonman

Racescort666

> thisisamazonman

02/04/2014 at 10:33 |

|

You could have the truck operated by hydraulic and the trailer operated by air but then you'd have to have 2 braking systems on board the truck. With dry break fittings, you could probably eliminate the need to bleed the system.

A hydraulic brake system in a car multiplies the force of your foot on the brake pedal. In an air brake system, the force comes from the pressurized air in the air tanks and your foot (on the treadle valve) releases air from the tanks to the brake chambers.

Fragile_this_side_up

> Boss2452stolemylunchmoney

Fragile_this_side_up

> Boss2452stolemylunchmoney

02/04/2014 at 10:34 |

|

Also, hooking up and detaching trailers could then also let air in the system of a hyrdaulic line..

olddatto

> Boss2452stolemylunchmoney

olddatto

> Boss2452stolemylunchmoney

02/04/2014 at 10:37 |

|

Also think about this, When you hook up a trailer, if there were Hydraulic brakes youd have to work out a way not to get air in the lines when changing trailers. Also bleeding brakes is already a pain in the ass, now add three more axles, and a few gallons of fluid. and trying to get air bubbles out of a 40ft trailer sounds like a nightmare.

Racescort666

> Sky Blue

Racescort666

> Sky Blue

02/04/2014 at 10:38 |

|

Ha, talk to Tanner Foust about drifting a bus. Skip to about 5:00

olddatto

> M54B30

olddatto

> M54B30

02/04/2014 at 10:40 |

|

That makes me feel better about riding next to rigs on the interstate. My Roommate works for Werner and I've heard stories about people getting hired there who have no business in a rig. One guy got his CDL on a box truck, and had never driven with a trailer before getting the job at werner.

Racescort666

> satalac

Racescort666

> satalac

02/04/2014 at 10:41 |

|

One of the mechanics I worked with said that they upgraded Chicago's snowplow fleet to an ESP system. He said it was a night and day difference. They could drive on half ice/half pavement slam on the brakes and the truck would stay perfectly straight.

Stang70Fastback

> Sky Blue

Stang70Fastback

> Sky Blue

02/04/2014 at 10:45 |

|

Been there, done that.

Yes, it is absolutely as fun as it sounds ;)

jnecr

> ChuckFickens

jnecr

> ChuckFickens

02/04/2014 at 10:49 |

|

This right here is why they use air and not hydraulic...

dogisbadob

> Racescort666

dogisbadob

> Racescort666

02/04/2014 at 10:51 |

|

Too bad American trucks still use drum brakes and no synchromesh.

satalac

> Racescort666

satalac

> Racescort666

02/04/2014 at 10:52 |

|

I hope this takes off with a lot of fleets. Emergency braking in a big truck is not fun at all.

Racescort666

> satalac

Racescort666

> satalac

02/04/2014 at 10:55 |

|

It's only a matter of time before it's mandatory. Passenger cars are already required to have stability control. Heavy trucks are only required to have ABS although this was the norm for passenger cars not too long ago.

drdude

> thisisamazonman

drdude

> thisisamazonman

02/04/2014 at 10:55 |

|

To rephrase what he was saying:

With car style hydraulic brakes, your foot is putting the pressure on the brakes.

With truck style air brakes, the engine makes pressure to apply the brakes, your foot just controls where that pressure goes.

MFEJAL grey because who knows...

> Ralstig

MFEJAL grey because who knows...

> Ralstig

02/04/2014 at 10:58 |

|

That excuse is not longer acceptable, because aviation uses hydraulics, and not air. And they now a thing or two about air. And reliability.

I remember walking the yard, draining air deposits, and getting gallons of water from them. Once I ask the yard mechanic to come with me, and he was surprised. Why nobody drain the tanks during post-trip? he asked. I laughed. Nobody was doing post-trip, pre-trips, nothing. Just let it idle for half and hour and then take off.

You way ask why? because laziness.

captnsug

> Racescort666

captnsug

> Racescort666

02/04/2014 at 11:01 |

|

I "test drove" whatever bullshit stability control system they were trying to put on our trucks down Cabbage Hill on I-84. Cabbage is undoubtedly the worst grade on the interstates; Donner and The Divide don't really come close.

It was wet (not slick), I had to use the Jake and I was grossing 78,000 lbs.

Long story short I came very close to taking an escape ramp. I was losing my trailer to the passengers side pretty much the whole way down but especially at the switchbacks I had to dump the clutch to straighten it out. You do not want to freeball it down Cabbage at 78, that's not enjoyable. Got up to 68 mph at one and point and did smoke the brakes about 2/3rds the way down. I don't know why this happened, I don't know if I was doing it wrong or something was fucked up, but I wrote my little report saying if these are standardized in the company I'm quitting. It's been almost 8 months, and it hasn't been brought up since. I doubt I was the only one with problems.

victor

> Racescort666

victor

> Racescort666

02/04/2014 at 11:10 |

|

Interesting read. I would argue that many passenger car drivers also find themselves in similar situations.

Turning off ESP is fun on the track or in off road situations, but ESP has a real life-saving component to it on the road; for all vehicles of all shapes and sizes.

People bitch about the electronic nannies here all the time, but I bet you soup to nuts most people probably can't even tell if it's on or off most of the time. The only time you can probably tell is going to be when it saves your ass on the road.

Maxaxle

> Racescort666

Maxaxle

> Racescort666

02/04/2014 at 11:16 |

|

I noticed that the video's trucks used training wheels (or stabilizing wheels) to prevent damage to the trailers and trucks involved; why not make a system with automated fold-out stabilizing wheels for when things get really bad? The only problems I can think of would be the length of each stabilizer (i.e. when the wheel goes down, who or what will be in its way?) and response (i.e. it's not easy to get a large mass going quickly enough to stop a much larger mass in time, but it's harder still to do so without smashing anything that happens to be in the way).

David E. Davis

> Racescort666

David E. Davis

> Racescort666

02/04/2014 at 11:17 |

|

I just want to drift a Greyhound.

Cé hé sin

> dogisbadob

Cé hé sin

> dogisbadob

02/04/2014 at 11:19 |

|

Drum brakes are widely used, not just in America. They are particularly common in off road use because they're not likely to be jammed by stray stones.

They still use crash boxes because they're cheaper, lighter and more durable and (not least) because of tradition. Automated boxes are nearly universal in long haul trucks in Europe but they're usually non synchro for the same reasons. The electronics control the box and engine accurately enough that they can dispense with synchro.

theturbovanman25

> dogisbadob

theturbovanman25

> dogisbadob

02/04/2014 at 11:21 |

|

An unsynchronized transmission is more reliable and cheaper. And trucks still use drum brakes since they are cheaper and meet nhtsa regulations. Drum brakes are fine as long as you aren't riding them getting them hot. But as disc brakes cost drops, they will start to become the norm

Smorgasborg

> Racescort666

Smorgasborg

> Racescort666

02/04/2014 at 11:32 |

|

Very interesting post!

EDIT: Dammit, wrong Bendix! Seriously, how many companies called Bendix can there be? More than one, I guess.

M54B30

> Racescort666

M54B30

> Racescort666

02/04/2014 at 11:33 |

|

Very true, but there's no stability control endorsement. I mentioned the air brakes because it's required for Class 8/ Class A drivers and some class b. The complexity of Stability control is a necessary evil, and one that has saved countless lives so far.

M54B30

> olddatto

M54B30

> olddatto

02/04/2014 at 11:37 |

|

That's weird. You have to supply the vehicle for your test that you'll be driving. You can't bring a box truck and get a school bus endorsement, you can't bring a school bus and use it to get a Class A license. Weird.

kschang

> Boss2452stolemylunchmoney

kschang

> Boss2452stolemylunchmoney

02/04/2014 at 11:47 |

|

Because offroad trucks don't reach speed of 70 MPH.

jvallido

> Racescort666

jvallido

> Racescort666

02/04/2014 at 11:48 |

|

dat drift action at:58

NipperDawg

> Boss2452stolemylunchmoney

NipperDawg

> Boss2452stolemylunchmoney

02/04/2014 at 11:48 |

|

It is much easier to connect various pieces of road going equipment to the tractor brakes using a air system as opposed to a hydraulic system. Air brakes can apply more force to the brakes then a hydraulic system can (without the complicated plumbing). Air systems are lower maintenance and lower cost. They do have their down sides like freezing in the winter if not properly prepared (don't know if they have self adjusters on them), low air pressure truck doesn't move, and time delay between application of tractor brakes vs last axle on a trailer set, but all in all, it is the ability to disconnect trailers simply is the hands down winner.

Rock Bottom

> desertdog5051

Rock Bottom

> desertdog5051

02/04/2014 at 11:52 |

|

I know that stretch of 80 well. Every time I drive that highway I think of how hard it must be in a truck. It's curvy too!

Boss2452stolemylunchmoney

> ChuckFickens

Boss2452stolemylunchmoney

> ChuckFickens

02/04/2014 at 11:53 |

|

Not with lossless couplers, which exist.

kschang

> Racescort666

kschang

> Racescort666

02/04/2014 at 11:54 |

|

You thought this is cool, you haven't seen the European racing trucks. :)

They heat up the brakes so much, they have WATER SPRAY SYSTEMS to keep the front brakes cool.

Boss2452stolemylunchmoney

> Racescort666

Boss2452stolemylunchmoney

> Racescort666

02/04/2014 at 11:56 |

|

Cat's hydraulic brakes work the same way. No mechanical force multiplication... Hydraulic pumps so the work. But I see the point about needing to overhaul the entire trucking system to make it work.

kschang

> Ralstig

kschang

> Ralstig

02/04/2014 at 11:56 |

|

Slight clarification. Once the fluid leaked there's no 'reserve' to replenish it.

In an air system, the compressor is adding more air to the system as long as the engine runs. So slow leaks are always replenished and doesn't affect performance. Only catastrophic leaks can sideline an airbrake system. it's far more fault tolerant than hydraulic brake system.

Boss2452stolemylunchmoney

> BigHarv

Boss2452stolemylunchmoney

> BigHarv

02/04/2014 at 11:57 |

|

Lossless couplers are a thing that exists.

Boss2452stolemylunchmoney

> Old-Busted-Hotness

Boss2452stolemylunchmoney

> Old-Busted-Hotness

02/04/2014 at 12:00 |

|

Moot point. Cat trucks have Vmax over 40 mph and have max weights over 1 million pounds. They employ oil cooled wet multidisk brakes and expel the heat during retarding (that's what it's called, really) through a massive radiator on the front of the machine.

Boss2452stolemylunchmoney

> Old-Busted-Hotness

Boss2452stolemylunchmoney

> Old-Busted-Hotness

02/04/2014 at 12:01 |

|

Moot point. Cat trucks have Vmax over 40 mph and have max weights over 1 million pounds. They employ oil cooled wet multidisk brakes and expel the heat during retarding (that's what it's called, really) through a massive radiator on the front of the machine.

Boss2452stolemylunchmoney

> Old-Busted-Hotness

Boss2452stolemylunchmoney

> Old-Busted-Hotness

02/04/2014 at 12:01 |

|

Moot point. Cat trucks have Vmax over 40 mph and have max weights over 1 million pounds. They employ oil cooled wet multidisk brakes and expel the heat during retarding (that's what it's called, really) through a massive radiator on the front of the machine.

czechmonsterdeux

> Boss2452stolemylunchmoney

czechmonsterdeux

> Boss2452stolemylunchmoney

02/04/2014 at 12:06 |

|

Operating temperature is one of the main reasons, air doesn't overheat since it's continually regenerated unlike brake fluid. Maintenance is another issue.

Boss2452stolemylunchmoney

> kschang

Boss2452stolemylunchmoney

> kschang

02/04/2014 at 12:06 |

|

They go over 40 mph, carry massive loads, and have to desk with steeper and more frequent grades. They use multi disk wet brakes with massive oil coolers to do the job.

Ad_absurdum_per_aspera

> Boss2452stolemylunchmoney

Ad_absurdum_per_aspera

> Boss2452stolemylunchmoney

02/04/2014 at 12:08 |

|

Air brakes make it easy to couple and decouple multiple units, and are pretty tolerant of minor faults such as leakage as long as you can keep the compressor going and have some air storage. What's more, both the action and the fault tolerance are easy to make distributed. Thus there's some overlap between hydraulic and air brakes in the middle range of straight trucks and buses/RV's, but semis all use air brakes.

If you think it's a big advantage for trucks — and it is — imagine what a revolution it must have been in railroads. That's the context in which George Westinghouse (yes, that Westinghouse, an inventor and industrialist who also loomed large in the early days of electrical power) invented the things; when automotive trucking started to become important the system was evolved to fit its needs.

kschang

> Boss2452stolemylunchmoney

kschang

> Boss2452stolemylunchmoney

02/04/2014 at 12:10 |

|

And since they don't go out of site and thus far away from support teams... :)

Boss2452stolemylunchmoney

> NipperDawg

Boss2452stolemylunchmoney

> NipperDawg

02/04/2014 at 12:10 |

|

You use hydraulic pumps to power the brakes on large equipment. Lossless couplers make changing equipment easy.

Racescort666

> captnsug

Racescort666

> captnsug

02/04/2014 at 12:11 |

|

It's certainly understandable that there is more development work that needs to be done with the systems. ABS was shit when it first came out on passenger cars. Same goes for ESP. I would argue that Ford's ESP is still shit but as the technology progresses it's not unreasonable to expect improvement.

The biggest takeaway is that this is a step in the right direction. I mentioned in another thread that it's only a matter of time before ESP is mandatory like it is on passenger cars. I would expect these issues to be resolved by that time.

Racescort666

> kschang

Racescort666

> kschang

02/04/2014 at 12:15 |

|

I'm familiar with this series. There's a series started by the Chump Car guys for trucks that's like this too: http://www.champtruck.us.com/

Boss2452stolemylunchmoney

> kschang

Boss2452stolemylunchmoney

> kschang

02/04/2014 at 12:17 |

|

Customers still demand extremely high up time (reliability) on them. When one if these machines has a break down, it's a huge deal. Customers get very upset because they're not just inconvenienced by downtime, they're losing money. In certain applications, a single day of downtime can write-off the value of the machine. Now think about having to tow one of these machines that's stuck on a 10% grade. Most of these machines will go 5-10 thousand hours between brake system rebuilds... Think about how many hours your car goes between brake system rebuilds!

Racescort666

> Maxaxle

Racescort666

> Maxaxle

02/04/2014 at 12:17 |

|

Trucks are already at the maximum legal width (although you can get a permit to go wider). This would probably be more expensive and less effective than stability control since it doesn't prevent jackknifing or understeer only rollover.

Racescort666

> David E. Davis

Racescort666

> David E. Davis

02/04/2014 at 12:17 |

|

Don't we all...

SynchroMess (K.S.O.F.M)

> Boss2452stolemylunchmoney

SynchroMess (K.S.O.F.M)

> Boss2452stolemylunchmoney

02/04/2014 at 12:20 |

|

Wet discs are get on something that already has a dedicated hydraulic system, they wear better etc, but on a tractor truck the added weight , among other reasons, would negate the benefits.

BigHarv

> Boss2452stolemylunchmoney

BigHarv

> Boss2452stolemylunchmoney

02/04/2014 at 12:39 |

|

True. Looking into it, apparently it's a historic thing as much as anything else. Air brakes that fail closed are originally from trains; trucks use them as easy fail-safe technology. Some people claim that a leak is easier to deal with, but a fail-safe hydraulic system should be pretty similar to deal with; other suggest that not having to have a ton of brake fluid is convenient, but I don't think the volume of brake fluid needed would be a dealbreaker. It seems like it's a system that is well described at this point and there is little push to design a redundant hydraulic equivalent.

I am curious about the lossless connectors-do they keep air out?

kschang

> Boss2452stolemylunchmoney

kschang

> Boss2452stolemylunchmoney

02/04/2014 at 12:41 |

|

One of those offroad haulers cost up to 5 MILLION, and their hydraulic fluid levels are supposed to be checked every 10 service hours or daily. if there's any alarm they head for the barn and will not need to be towed. They rarely if ever see catastrophic failures.

Not so with highway haulers. You can buy a nice example for 50K. And they often don't enjoy daily maintenance.

Mattbob

> Racescort666

Mattbob

> Racescort666

02/04/2014 at 12:51 |

|

" kind of like a transistor"

Whoa there.... What do you mean by this? A MOSFET? A BJT??? I don't think this analogy is helpful here, or necessarily makes sense.

Mattbob

> Mattbob

Mattbob

> Mattbob

02/04/2014 at 12:56 |

|

nevermind. I don't feel like getting into it. Sure, it's like a transistor.

Lotusexcelle

> thisisamazonman

Lotusexcelle

> thisisamazonman

02/04/2014 at 13:00 |

|

Air brakes do multiply the force. I'll keep it in tl:dr format but - the PSI of the air system, say 100psi, is multiplied by the size of the brake chamber. So a 30 square in chamber gives you 3,000psi of force or "stroke". Then multiply that by the length of the slack adjuster - say 5 inches, and you get quite a bit of torque twisting your s-cam... which pushes the brake shoes against the drum.

MrEvil

> ChuckFickens

MrEvil

> ChuckFickens

02/04/2014 at 13:01 |

|

Use electric over hydraulic for trailer brakes (many gooseneck trailers already use those type of brakes). They also make quick-connects for hydraulic lines that don't require bleeding, ag equipment has had them for decades and the newest fittings do an even better job of retaining fluid than the earlier fittings.

Lotusexcelle

> Racescort666

Lotusexcelle

> Racescort666

02/04/2014 at 13:04 |

|

Saying air brakes do not multiply force is false. Air brakes are sized according to diaphragm size is square inches (in the US). A 30 chamber is 30 square inches, so 100psi can now push with 3,000 pounds of force. Add the slack adjuster length, which can be considered a torque multiplier, and the s-cam profile...

So yes air brakes multiply force.

Boss2452stolemylunchmoney

> BigHarv

Boss2452stolemylunchmoney

> BigHarv

02/04/2014 at 13:12 |

|

Not really certain, but I would think you could design them multiple ways. One design could be two inline slave cylinders.

BLOZUP

> Racescort666

BLOZUP

> Racescort666

02/04/2014 at 13:18 |

|

Where do I sign up to be a truck stability systems tester?

elvis-is-french-and-alive

> Boss2452stolemylunchmoney

elvis-is-french-and-alive

> Boss2452stolemylunchmoney

02/04/2014 at 13:32 |

|

Trucks can have a retarder (to spare the main brake) based on an hydraulic or an electric system and/or an exhaust one. you use a lever with 2 to 5 levels which command it.

It will brake the rear axle of your tractor and can be coupled to your main brake. And that is one of the reason trucks end in ditch on the wet/snow.

Racescort666

> Mattbob

Racescort666

> Mattbob

02/04/2014 at 13:38 |

|

Sorry, I'm a mechanical engineer and my understanding of transistors is limited. Smaller voltage controlling a larger voltage.

Racescort666

> Lotusexcelle

Racescort666

> Lotusexcelle

02/04/2014 at 13:39 |

|

They don't multiply the force of your foot on the pedal.

Boss2452stolemylunchmoney

> kschang

Boss2452stolemylunchmoney

> kschang

02/04/2014 at 13:41 |

|

No reason not to expect daily inspections. I'm surprised USDOT doesn't require them.

GrauGeist

> kschang

GrauGeist

> kschang

02/04/2014 at 13:42 |

|

Also run in Brazil. Awesome.

GT921

> David E. Davis

GT921

> David E. Davis

02/04/2014 at 14:10 |

|

I'm glad I'm not the only one who thought that haha. That looked like a lot of fun. A bit less terrifying than a truck.

Mattbob

> Racescort666

Mattbob

> Racescort666

02/04/2014 at 14:18 |

|

transistors can be current driven instead of voltage driven. MOSFETs are voltage driven, while BJTs are current driven. Your example, was close enough. I was just nitpicking.

kschang

> Boss2452stolemylunchmoney

kschang

> Boss2452stolemylunchmoney

02/04/2014 at 14:25 |

|

Technically it's a part of pre-run checkup, but how many miles do one of those offroaders run per day, vs. hauler?

kschang

> GrauGeist

kschang

> GrauGeist

02/04/2014 at 14:26 |

|

You sure those aren't RC toys? ;) They have that slightly -off look that toys do. :D

Cé hé sin

> Racescort666

Cé hé sin

> Racescort666

02/04/2014 at 14:27 |

|

I see that while most of the pictures here are from North American trucks, this one certainly isn't. How do I know?

Cé hé sin

> olddatto

Cé hé sin

> olddatto

02/04/2014 at 14:33 |

|

You're allowed do this (drive an artic on a rigid licence) in America??

GrauGeist

> kschang

GrauGeist

> kschang

02/04/2014 at 14:36 |

|

OK, I used to race 1/10 street and a 1/10 RC series with those bodies would be pretty awesome!

I googled, and racing semi truck bodies do exist for 1/10 scale RC cars:

Note that how the wheels attach with center hub bolt, versus as pictured.

And those racing trucks do exist like that, go google for yourself. It's very cool stuff.

kschang

> GrauGeist

kschang

> GrauGeist

02/04/2014 at 14:41 |

|

I know, thus the winkie ;)

GrauGeist

> kschang

GrauGeist

> kschang

02/04/2014 at 14:43 |

|

I wasn't sure if you knew I did RC sedans and was winking about the old Yokomo RTH truck bodies.

It's all good.

What I kinda want right now is one of these bodies:

Seriously, what RC racer doens't want a big white van running around the track?

olddatto

> Cé hé sin

olddatto

> Cé hé sin

02/04/2014 at 14:54 |

|

I heard the story second hand, but from what I heard the guy had NEVER driven with a trailer and had his CDL.

Racescort666

> Cé hé sin

Racescort666

> Cé hé sin

02/04/2014 at 15:17 |

|

24 volt operation. Could be military, they use 24 volt too. But I think that might be a Knorr Bremse ABS modulator. I certainly could have done this entire article from Bendix promotional material though.

Cé hé sin

> Racescort666

Cé hé sin

> Racescort666

02/04/2014 at 15:25 |

|

...is the right answer. There's probably some reason, shrouded in history, why much of the world uses 24v trucks and North America finds 12v sufficient.

I'm told that your military uses 24v to stop people stealing parts.

Cé hé sin

> olddatto

Cé hé sin

> olddatto

02/04/2014 at 15:48 |

|

Wouldn't be allowed here! There's a class C licence (rigid) and C + E (artic).

Old-Busted-Hotness

> Boss2452stolemylunchmoney

Old-Busted-Hotness

> Boss2452stolemylunchmoney

02/04/2014 at 16:00 |

|

And this technology became available when? Air brakes have been around a lot longer than trucks have. Air brakes are simple enough for a truck driver to repair or adjust if needed, are self-bleeding, and connecting/disconnecting the trailer takes 30 seconds. Plus they're cheap. That's gonna be your answer right there.

Racescort666

> Cé hé sin

Racescort666

> Cé hé sin

02/04/2014 at 16:21 |

|

Not sure if the part stealing is true. I heard a rumor that they were considering switching to a 36 volt system because of how much electronics they are using on combat vehicles now though.

ChuckFickens

> Boss2452stolemylunchmoney

ChuckFickens

> Boss2452stolemylunchmoney

02/04/2014 at 16:44 |

|

OK... this is a reply to everyone that has made a similar comment about lossless couplers and/or air/hydraulic systems...

They are great I'm sure, until you get sent to the docks to haul a 20 year old trailer that only has an air system

Tractor units aren't linked to one trailer, they have to be able to haul any tailer they are sent out to, air brakes work and it's the standard, why change a standard that works?

Boss2452stolemylunchmoney

> ChuckFickens

Boss2452stolemylunchmoney

> ChuckFickens

02/04/2014 at 17:15 |

|

Yeah changing an entire fleet would be painful. But it may be necessary some day in increase response times for the control systems.

Dr. Strangegun

> Boss2452stolemylunchmoney

Dr. Strangegun

> Boss2452stolemylunchmoney

02/05/2014 at 09:25 |

|

So are lossy leaks.

Cé hé sin

> Racescort666

Cé hé sin

> Racescort666

02/05/2014 at 14:05 |

|

That's probably something like the report done years ago that several car makers were thinking of 42v although nothing came of it at the time. The reasons are probably the same and I expect that with the increasing use of electronics for everything we'll hear more about this.

JayR727

> Racescort666

JayR727

> Racescort666

03/01/2014 at 23:39 |

|

So if the system senses a rollover, it shoots out training wheels. Brilliant!!1! Great post, mate. Also cool how Bendix is selling the system to multiple manufacturers, rather than limit to just one big rig maker.